Xylene

| Infobox on Xylene | |

|---|---|

| Example of Xylene |  |

| Facts | |

| Origin | - |

| Stowage factor (in m3/t) | - |

| Humidity / moisture | - |

| Ventilation | - |

| Risk factors | See text |

Xylene

Description

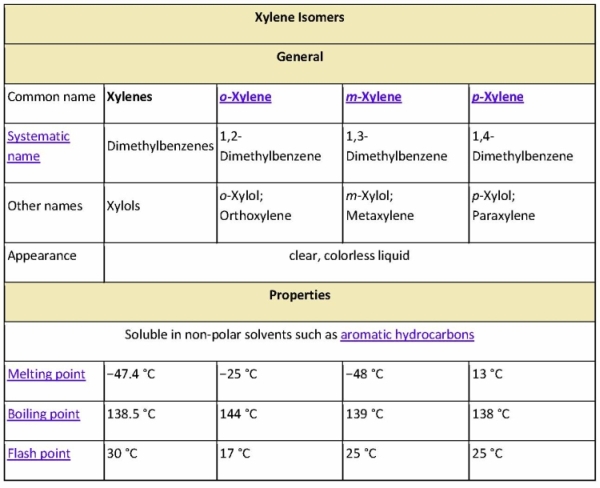

Xylenes encompass three isomers of dimethylbenzene. The isomers are distinguished by the designations ortho- (o-), meta- (m-), and para- (p-), which specify to which carbon atoms (of the benzene ring) the two methyl groups are attached. Counting the carbon atoms around the ring starting from one of the ring carbons bonded to a methyl group, and counting towards the second methyl group, the o-isomer has the IUPAC name of 1,2-dimethylbenzene, the m-isomer is 1,3-dimethylbenzene, and the p-isomer is 1,4-dimethylbenzene.

Some chemical and physical properties differ from isomer to isomer. The melting point ranges from −47.87 °C (m-xylene) to 13.26 °C (p-xylene). The boiling point for each isomer is around 140 °C. The density of each is around 0.87 g/mL and thus is less dense than water. Xylene in air can be smelled at concentrations as low as 0.08 to 3.7 ppm (parts of xylene per million parts of air) and can begin to be tasted in water at 0.53 to 1.8 ppm.

The xylenes are major petrochemicals, produced by catalytic reforming and also by coal carbonisation in the manufacture of coke fuel. Representing about 0.5–1% of Crude Oil (depending on the source), xylenes are found in small quantities in gasoline and airplane fuels. Xylenes are mainly produced as part of the BTX aromatics (benzene, toluene and xylenes) extracted from the product of catalytic reforming known as "reformate". The mixture is a slightly greasy, colourless liquid commonly encountered as a solvent.

Xylenes are produced by dehydrocyclodimerization and by methylating of toluene and benzene. Via the Isomar process, the ratio of isomers can be shifted to favour p-xylene, which is most valued. This conversion is catalyzed by zeolites.

Application

Terephthalic acid and related derivatives

p-Xylene is the principal precursor to terephthalic acid and dimethyl terephthalate, both monomers used in the production of polyethylene terephthalate (PET) plastic bottles and polyester clothing. 98% of p-xylene production, and half of all xylene, is consumed in this way. o-Xylene is an important precursor to phthalic anhydride. The demand for isophthalic acid is relatively modest so m-xylene is rarely sought (and hence the utility of its conversion to the o- and p-isomers).

Solvent applications

Xylene is used as a solvent. In this application, the mixture of isomers is often referred to as xylenes or xylol. Solvent xylene often contains a small percentage of ethylbenzene. Like the individual isomers, the mixture is colorless, sweet-smelling, and highly flammable. Areas of application include printing, rubber, and leather industries. It is a common component of ink, rubber, adhesive, and leather industries. In thinning paints and varnishes, it can be substituted for toluene where slower drying is desired, and thus is used by conservators of art objects in solubility testing. Similarly it is a cleaning agent, e.g., for steel, silicon wafers, and integrated circuits. In dentistry, xylene can be used to dissolve Gutta Percha, a material used for endodontics (root canal treatments). In the petroleum industry, xylene is also a frequent component of paraffin solvents; used when the tubing becomes clogged with paraffin wax.

Laboratory uses

It is used in the laboratory to make baths with dry ice to cool reaction vessels, and as a solvent to remove synthetic immersion oil from the microscope objective in light microscopy. In histology, xylene is the most widely used clearing agent. Xylene is used to remove paraffin from dried microscope slides prior to staining. After staining, microscope slides are put in xylene prior to mounting with a coverslip.

Precursor to other compounds

Although conversion to terephthalic acid is the dominant chemical conversion, xylenes are precursors to other chemical compounds. For instance chlorination of both methyl groups gives the corresponding xylene dichlorides (bis(chloromethyl)benzenes) whilst monobromination yields xylyl bromide, a tear gas-agent used in World War I.

Safety

Xylene is flammable but of modest acute toxicity, with LD50 ranges from 200 to 4000 mg/kg for animals. The principal mechanism of detoxification is oxidation to methylbenzoic acid and hydroxylation to hydroxylene.

Summary of uses:

- Xylene; aviation gasoline, protective coatings, solvent for alkyd resins, lacquers, enamels, rubber cements, synthesis of organic chemicals.

- M-xylene; solvent, intermediate for dyes and organic synthesis, especially isophthalic acid, insecticides, aviation fuel.

- O-xylene; manufacture of phthalic anhydride, vitamin and pharmaceutical syntheses, insecticides, motor fuels.

- P-xylene; synthesis of terephthalic acid for polyester resins and fibers, vitamin and pharmaceutical synthesis, insecticides.

Shipment / Storage

Xylene is practically insoluble in water; it is however soluble in non-polar solvents such as aromatic hydrocarbons.

For overseas carriage aspects of Chemicals, the readers are recommended to acquire or have access to a good chemical dictionary, and a copy of the International Maritime Dangerous Goods (IMDG) Code, issued by the International Maritime Organisation. Also consult the applicable MSDS sheet.

Risk factors

Flammable, moderate fire risk. Toxic by ingestion and inhalation. TLV: 100 ppm in air.

See also: http://www.chemicalland21.com/petrochemical/o-XYLENE.htm

http://www.chemicalland21.com/petrochemical/p-XYLENE.htm