Difference between revisions of "Magnesite"

m (→Description / Application) |

m (→Shipment / Storage / Risk factors) |

||

| Line 67: | Line 67: | ||

==Shipment / Storage / Risk factors== | ==Shipment / Storage / Risk factors== | ||

| − | + | Contact with water is unlikely to harm this commodity, as the tendency would be to wash away impurities. However, sea water affection has often yielded claims as the chlorides seem to adversely affect the production process. | |

| − | |||

| − | |||

[[Category:Products]] | [[Category:Products]] | ||

[[Category:Minerals and rocks]] | [[Category:Minerals and rocks]] | ||

Latest revision as of 13:22, 14 January 2021

| Infobox on Magnesite | |

|---|---|

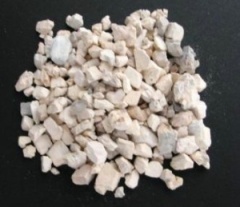

| Example of Magnesite |  |

| Facts | |

| Origin | Austria, Bahia, Brazil, Korea, China, California, USA and many European localities. |

| Stowage factor (in m3/t) | 1,00 m3 (big bags) |

| Humidity / moisture | - |

| Ventilation | - |

| Risk factors | See text |

Magnesite

Description / Application

A white, yellowish or brown crystalline solid used in the manufacture of refractories. Magnesite can be used as a slag former in steelmaking furnaces, in conjunction with lime, in order to protect the magnesium oxide lining. It can also be used as a catalyst and filler in the production of synthetic rubber and in the preparation of magnesium chemicals and fertilizers.

Similar to the production of lime, magnesite can be burned in the presence of charcoal to produce MgO, otherwise known as periclase. Such periclase is an important product in refractory materials.

Magnesite can also be used as a binder in flooring material.

In fire assay, magnesite cupels can be used for cupellation as the magnesite cupel will resist the high temperatures involved.

Dead burned magnesite is selected from natural magnesite, it is produced by mine-selecting, purifying, calcining in shaft kilns. It is an ideal material for unshaped refractory material, the final products are used in opening hearth furnace, electric furnace bottom furnaces lining tamping. Dead burned magnesite ( middle grade ) is made from sorted natural raw magnesite through sintering in high temperature shaft kilns. They are ideal materials for making monolithic refractories. Their finished products are also used for making the bottoms or lining of open-hearth furnace and electric arc furnace.

Magnesite does not ordinarily form good crystals, but can make up a substantial portion of some rock types. It forms commonly from the alteration of magnesium-rich rocks during low grade metamorphism while they are in contact with carbonate-rich solutions. Magnesite has the same crystal structure of calcite, hence its inclusion into the calcite mineral group. Many of the properties of magnesite are either identical or similar to those of calcite. However, the magnesium ion does not allow the carbonate ion to interact as easily with cold acids, as the calcium ion does in calcite. This provides the best means of distinguishing magnesite from calcite. However, dolomite can be almost indistinguishable from magnesite.

Physical Characteristics

- Color is white or gray, also tinted yellow or brown.

- Luster is vitreous.

- Transparency crystals are translucent to transparent only in individual crystals.

- Crystal System is trigonal; bar 3 2/m

- Crystal Habits are usually massive forms such as lamellar, fiberous and course to fine grained rocks. Crystals are extremely rare, but when found are in the form of rhombohedrons or hexagonal prisms with a pinacoid termination.

- Cleavage is perfect in three directions forming rhombohedrons.

- Fracture is conchoidal to uneven.

- Hardness is 4 - 4.5.

- Specific Gravity is approximately 3.0 (average)

- Streak is white.

- Associated Minerals calcite, dolomite, aragonite, strontianite and serpentine.

- Other Characteristics: effervesces easily only in hot dilute hydrochloric acid.

- Notable Occurrences include Austria; Bahia, Brazil; Korea; China; California, USA and many European localities.

- Best Field Indicators are crystal habit, reaction to acid, occurrence and cleavage.

Uses

Dead-burned magnesia - DBM Sinter magnesia

- Basic refractories

Fused or electrofused magnesia - FM

- Thermal insulation (refractories)

- Electrical insulation (electric ovens and appliances)

Caustic-calcined magnesia - CCM

- Extraction of magnesium

- Production of fused magnesia

- Cement, Insulation

- Paper

- Fertilizer and animal feed

- Stabilizer during vulcanization of rubber

- Production of uranium

- Chemical and environmental applications (notably in water treatment and gas desulfurization)

Magnesite or Magnesium Carbonate (precipitated)

- Insulation, Rubber

- Paint pigments and Ink

- Glass and ceramics

- Chemistry

Brucite or magnesium hydroxide

- Sugar refining

- Flame and smoke retardants

- Chemical and environmental applications (notably in water treatment)

- Pharmaceuticals

Magnesium chloride

- Cement

- Ceramics and refractories

- Textiles, Paper

- Chemical applications

- Production of magnesium

Magnesium sulfate

- Pulp and paper

- Animal feed

- Pharmaceuticals

Shipment / Storage / Risk factors

Contact with water is unlikely to harm this commodity, as the tendency would be to wash away impurities. However, sea water affection has often yielded claims as the chlorides seem to adversely affect the production process.