Difference between revisions of "Aggregates"

(→Shipment / storage) |

(→Shipment / storage) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

| humidity and moisture = - | | humidity and moisture = - | ||

| ventilation = - | | ventilation = - | ||

| − | | risk factors = | + | | risk factors = Moisture, contamination. The IMSBC code should be consulted for product specific properties and risk factors. |

}} | }} | ||

__TOC__ | __TOC__ | ||

| Line 18: | Line 18: | ||

In addition, there are some (minor) materials that are used as specialty lightweight aggregates; for example clay, pumice, perlite, and vermiculite.<br><br> | In addition, there are some (minor) materials that are used as specialty lightweight aggregates; for example clay, pumice, perlite, and vermiculite.<br><br> | ||

| − | ==Shipment / | + | ==Shipment / Storage== |

The material consist of dry bulk of varying size (e.g. fines, particles, lumps or bricks) and can be shipped in a variety of ways, subject to customers’ demands (e.g. shipping as a solid bulk product, in (big) bags, or other packed form and carriage in general purpose containers).<br><br> | The material consist of dry bulk of varying size (e.g. fines, particles, lumps or bricks) and can be shipped in a variety of ways, subject to customers’ demands (e.g. shipping as a solid bulk product, in (big) bags, or other packed form and carriage in general purpose containers).<br><br> | ||

Depending on specific product characteristics, special storage and carriage requirements may be applicable. These requirements may include for example; dry (closed) storage, avoiding wetting during handling and carriage and avoiding contamination.<br><br> | Depending on specific product characteristics, special storage and carriage requirements may be applicable. These requirements may include for example; dry (closed) storage, avoiding wetting during handling and carriage and avoiding contamination.<br><br> | ||

| Line 26: | Line 26: | ||

* Moisture damage (seawater) | * Moisture damage (seawater) | ||

* Contamination (defilement) | * Contamination (defilement) | ||

| + | * The IMSBC code should be consulted for product specific properties and risk factors | ||

[[Category: Products]][[Category: Minerals and rocks]] | [[Category: Products]][[Category: Minerals and rocks]] | ||

Latest revision as of 08:38, 11 May 2020

| Infobox on Aggregates | |

|---|---|

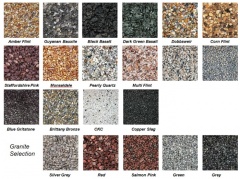

| Example of Aggregates |  |

| Facts | |

| Origin | Various |

| Stowage factor (in m3/t) | stowage factor = Some examples: Lightweight aggregates:

Lightweight aggregates:

|

| Humidity / moisture | - |

| Ventilation | - |

| Risk factors | Moisture, contamination. The IMSBC code should be consulted for product specific properties and risk factors. |

Aggregates

Description

Construction aggregate, or simply "aggregate", is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Products come usually in the form of dry bulk.

Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains, and road side edge drains. Aggregates are also used as base material under foundations, roads, and railroads. To put it another way, aggregates are used as a stable foundation or road/rail base with predictable, uniform properties (e.g. to help prevent differential settling under the road or building), or as a low-cost extender that binds with more expensive cement or asphalt to form concrete.

The American Society for Testing and Materials publishes an exhaustive listing of specifications for various construction aggregate products, which, by their individual design, are suitable for specific construction purposes. These products include specific types of coarse and fine aggregate designed for such uses as additives to asphalt and concrete mixes, as well as other construction uses. State transportation departments further refine aggregate material specifications in order to tailor aggregate use to the needs and available supply in their particular locations.

Sources for these basic materials can be grouped into three main areas:

- Mining of mineral aggregate deposits, including sand, gravel, and stone.

- Waste slag from the manufacture of iron and steel.

- Recycled materials, which are chiefly manufactured from mineral aggregates.

In addition, there are some (minor) materials that are used as specialty lightweight aggregates; for example clay, pumice, perlite, and vermiculite.

Shipment / Storage

The material consist of dry bulk of varying size (e.g. fines, particles, lumps or bricks) and can be shipped in a variety of ways, subject to customers’ demands (e.g. shipping as a solid bulk product, in (big) bags, or other packed form and carriage in general purpose containers).

Depending on specific product characteristics, special storage and carriage requirements may be applicable. These requirements may include for example; dry (closed) storage, avoiding wetting during handling and carriage and avoiding contamination.

The carriage of dry bulk cargoes is subject to the provisions of the International Maritime Solid Bulk Cargoes Code (IMSBC-code). The subject publication should be consulted in the event that aggregates are carried.

Risk factors

- Moisture damage (seawater)

- Contamination (defilement)

- The IMSBC code should be consulted for product specific properties and risk factors